Siempelkamp Press Controller SPC G9

With intelligent pressure/position control

to a highly available ContiRoll®

In order to help shape the demands for digitalization in machine and plant engineering today and in the future, we have developed the now 9th generation of the intelligent pressure/position control system Siempelkamp Press Controller (SPC). The SPC G9 uses raw data from pressure/position sensors to control the desired press forces and distances in the technological press zones of the ContiRoll®. This means that in the area of press hydraulics, all hydraulic valves, pressure sensors and position encoders are based on this system, which makes the SPC G9 a core component. Therefore, we recommend stocking a replacement system that can be installed 1:1 and plug-and-play in the event of an SPC failure. After system restart, the system is thus immediately available again.

Brief profile

Features of SPC Gen. 9

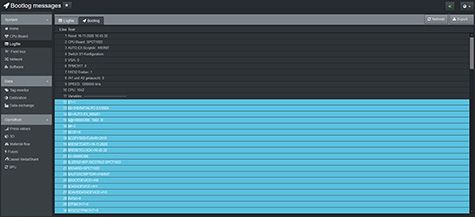

When modernizing existing plants, the new SPC generation G9 simply replaces the first and second generation SPC systems. PROFINET takes the place of the INTERBUS-S interfaces and after only minor adjustments, the programs for pressure / position control can be integrated. Established tool chains such as continuous hardware project planning remain intact after an upgrade to SPC. The SPC system has its own user interface, which is accessed via a standard browser. Here, the status of each input and output is visible. The interface can also be used for diagnostics and error analysis.

Overview

Your benefits

- Plant-specific configured system

- Minimized installation time

- Reduced downtime

These product advantages result in the following specific benefits for you:

Further information

Flyer: Siempelkamp Press Controller SPC Gen. 9Product page SPC G9Your contact and ordering

Aftersales Service

Tel. +49 671 796110-13

sales-sls@siempelkamp.com