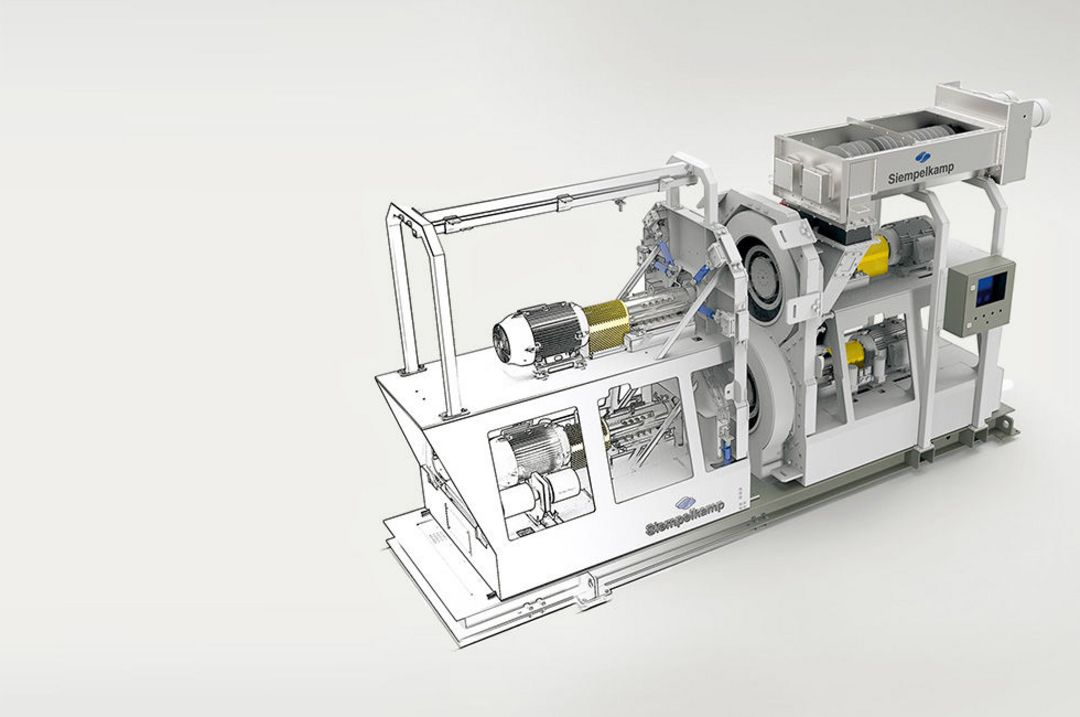

EcoPulser

EcoPulser

Up to 80% energy savings through innovative size reduction

Any kind of mechanical size reduction – for example, grinding, tearing or cutting absorbs energy by friction. The size-reduction method of the EcoPulser, based on shock waves, is a non-contact concept and is particularly energy efficient.

Brief profile

Low wear and highly efficient process

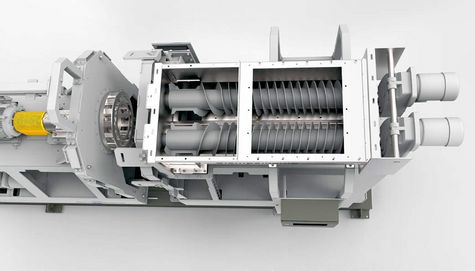

The EcoPulser provides a non-contact, low-wear size reduction of wood chips and the production of chips and surface layer material. Shock waves, generated by interferences of impacting pressure fronts, act on the material and thereby break the structure. Even heavily abrasive materials can be perfectly size reduced with this non-contact process. No cutting or impact edges are used for this type of size reduction. Therefore any re-sharpening or replacement of knives, hammers or other grinding elements is no longer necessary. An additional advantage: the EcoPulser is resistant to contaminants such as rocks or metal pieces, as there is no material contact with the vane rings. The result: High efficiency, low maintenance and high machine availability.

Overview

Features of the EcoPulser

- Flakes/chips structure is disintegrated by air pressure pulses

- Two high-speed rotors run in opposite direction

- Wings in rotors produce defined pressure pulses

- Functional principle: Disintegration of flakes takes place where two pressure pulses meet and generate under-pressure causing the cells to explode

Product advantages and customer benefits

Components with high potential

- Higher energy efficiency: compared to standard size reduction concepts energy savings of up to 80%

- Extremely low machine wear due to contactless size reduction

- Low maintenance costs due to long lifetime of tools

- Reduced risk of explosion due to high flow rate inside the machine

- High resistance against impurities such as stones, glass, plastic and smaller metallic parts

These product advantages result in the following specific benefits for you:

Further information

Brochure: EcoPulser – Size reduction per shock waves (EN)Your contact

Thomas Steeger

Tel. +49 2151 92-4691

thomas.steeger@siempelkamp.com